INSPECTING, TESTING, AND REPAIRING CYLINDER LINERS

Cylinder liners may become damaged or worn excessively. The following paragraphs discuss the more common causes and repairs.

CRACKED, BROKEN, AND DISTORTED LINERS

You should suspect one or more cylinder liners whenever you notice one of the following indications:

l Excessive water in the lubricating oil

l An accumulation of water in one or more cylinders of a secured engine

l An abnormal loss of water in the cooling system

l High cooling water temperature or fluctuating pressure (caused by combustion gases blowing into the water jacket)

l Oil in the cooling water

When you suspect that a liner is cracked, try to locate the cracks visually. If you cannot locate the cracks visually, use another testing method, such as the water pressure test or air pressure test described earlier. To check liners with integral cooling passages, plug the outlets and fill the passages with glycol-type antifreeze. This liquid will leak from even the smallest cracks. Cracks in dry liners may be more difficult to locate because there is no liquid to leak through the cracks. You may need to use magnaflux equipment or penetrating dye to locate these cracks.

Causes

Cylinder liners may crack because of poor cooling, improper fit of piston or pistons, incorrect installation, foreign bodies in the combustion space, or erosion and corrosion. Improper cooling, which generally results from restricted cooling passages, may cause hot spots in the liners, resulting in liner failure due to thermal stress. Scale formation on the cooling passage surfaces of liners may also cause hot spots; wet liners are subject to scale formation. You may remove the scale by following the procedures outlined in chapter 233 of the Naval Ships’ Technical Manual (NSTM).

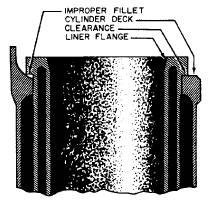

Proper cooling of dry liners requires clean contact surfaces between the liners and the cylinder block. Particles of dirt between these surfaces cause air spaces, which are poor conductors of heat. Films of oil or grease on these mating surfaces also resist the flow of heat. Distortion, wear, or breakage may result if a liner is not properly seated. Causes of improper liner seating may be metal chips, nicks, or burrs, or improper fillets, In figure 3-3 an improper fillet on the cylinder deck prevents the liner from seating properly. To correct an

—Improperly seated cylinder liner.

improper fillet, grind it down until the lower surface of the flange seats properly on the mating surface of the cylinder deck.

An oversized sealing ring may cause improper positioning of the liner. As the sealing ring is overcompressed, the rubber loses its elasticity and becomes hard, which may cause the liner to become distorted.

Use feeler gauges to check the clearance between the mating surfaces. If the manufacturer’s technical manual specifies the distance from the cylinder deck to the upper surface of the liner flange, use this dimension to check on the seating of the liner.

Obstructions in the combustion chamber may be destructive not only to the liner but also to the cylinder head and other parts.

Erosion and corrosion may take place in a few isolated spots and weaken a liner sufficiently to cause cracks.

Repairs

Replacement is the only satisfactory means of correcting cracked, broken, or badly distorted cylinder liners.

Thursday, November 11, 2010

INSPECTING, TESTING, AND REPAIRING CYLINDER LINERS

Labels:

REPAIRING CYLINDER LINERS