INSPECTING AND REPAIRING CAMSHAFTS

Camshafts can be saved when the cams alone are damaged, if the cams are of the individual type, since such cams may be removed and replaced. Figure 3-17 illustrates the method of removing an individual cam from its shaft.

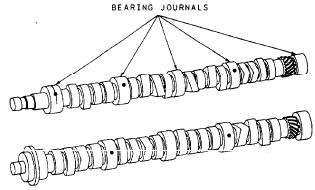

When you remove a camshaft from an engine, clean it thoroughly with either kerosene or diesel fuel. After cleaning the shaft, dry it with compressed air. After cleaning the cam and journal surfaces, inspect them for any signs of scoring, pitting, or other damage. When you remove or insert a camshaft through the end of the camshaft recess, rotate it slightly. Rotating the camshaft allows it to enter easily and reduces the possibility of damage to the cam lobes and bearings. After you visually inspect a camshaft, place it on V-blocks and measure the shaft runout by using a dial indicator. When you measure the runout, take the out-of-roundness into consideration. Compare your measurements to the manufacturer’s specifications. Also, measure the camshaft bearing journals with a micrometer. Figure 3-18 illustrates a camshaft with bearing journals.

A camshaft needs to be replaced if the following conditions occur:

1. The lobes are damaged, as lobes cannot be repaired.

2. Runout exceeds the manufacturer’s specifications.

3. Wear on the shaft bearing journals exceeds the manufacturer’s specifications.

4. The keyways are damaged.

—Camshaft with bearing journals in a V-type engine.

Before you reinstall a good camshaft, remove the minor surface defects on the cams and the camshaft by using crocus cloth or a fine stone.

Thursday, November 11, 2010

INSPECTING AND REPAIRING CAMSHAFTS

Labels:

REPAIRING CAMSHAFTS